Benzyl Deprotection

(H2 + Pd/C)

Examples:

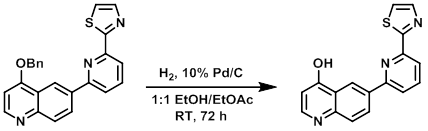

Example 1

To a solution of the SM (1.0 equiv) in 1:1 EtOH/EtOAc (0.1 M) was added 10% Pd/C (0.1 equiv). The resulting mixture was stirred under and atmosphere of H2 for 72 h, after which time it was filtered through a pad of celite eluting with EtOAc. The volatiles were removed in vacuo to provide the product. [88%]

[Patent Refernce: WO2010026121, page 60, ![]() (3.6 MB)]

(3.6 MB)]

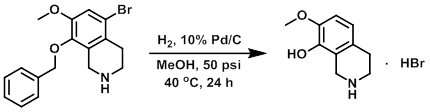

Example 2

To a solution of the SM (9.3 g, 27 mmol) in MeOH (300 mL) was added 10% Pd/C (2 g). The reaction mixture was hydrogenated (H2) at 50 psi for 24 h at 40 C, after which time the mixture was filtered and the filtrate concentrated in vacuo to provide the product as a white solid. [7.0 g, 100%]

[Patent Reference: WO2014177977, page 66, ![]() (6.0 MB)]

(6.0 MB)]

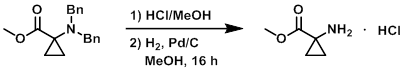

Example 3

The SM (4.0 g, 12.9 mmol) was treated with HCl/MeOH (20 mL) and concentrated to dryness in vacuo. The resulting gummy liquid was dissolved in MeOH (100 ml), followed by the addition of Pd/C(1.0 g). The reaction was stirred under H2 for 16 h, after which time the mixture was filtered through celite. The filtrate was concentrated in vacuo to provide the product as a light brown gummy liquid. [2.0 g, 93%]

[Patent Reference: WO2014149164, page 234, ![]() (23.7 MB)]

(23.7 MB)]

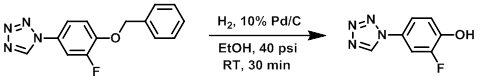

Example 4

To the SM (1.12 g, 4.14 mmol) in a Parr shaker flask was added EtOH (40 mL). The solution was purged with N2 and 10% Pd/C (0.30 g) was added. The reaction was hydrogenated on a Parr shaker apparatus under 40 psi H2 for 30 min. The mixture was filtered through a micro pore filter, and the filtrate was concentrated in vacuo to provide the product as a white solid which was used without further purification. [0.67 g, 90%]

[Patent Reference: WO2012069948, page 53, ![]() (3.9 MB)]

(3.9 MB)]

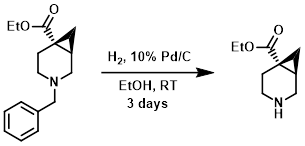

Example 5

A flask was charged with 10% Pd/C (0.25 g, 0.23 mmol) and the atmosphere was evacuated and refilled with argon three times. To the flask was added the SM (1.00 g, 3.86 mmol) in EtOH (40 mL). The reaction mixture was placed under an atmosphere of H2 and stirred at RT for 3 days. The mixture was filtered through celite and concentrated in vacuo to provide the product. [0.72 g, quant.]

[Patent Reference: WO2016014463, page 64, ![]() (6.7 MB)]

(6.7 MB)]