Boc Protection

(Boc2O + Base + DMAP)

Examples:

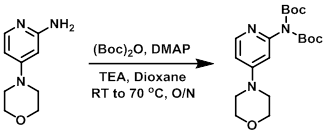

Example 1

The SM (1.082 g, 6.04 mmol), (Boc)2O (1.542 mL, 6.64 mmol), and TEA (1.010 mL, 7.24 mmol) were combined in dioxane (20 mL) to give a colorless solution. DMAP (0.738 g, 6.04 mmol) was added and the mixture was allowed to stir at RT for 2 h, after which time it was heated to 70 C for 1 h. An additional amount of (Boc)2O (2 g, 9.17 mmol) was added and the mixture was heated at 70 C overnight. The reaction was concentrated and diluted with DCM and H2O. The org layer was separated and washed with H2O, dried (Na2SO4), and concentrated. The resulting residue was triturated with diethyl ether, filtered, and further washed with diethyl ether to provide the pure product. [1.654 g]

[Patent Reference: WO2010038081, page 275, ![]() (33.8 MB)]

(33.8 MB)]

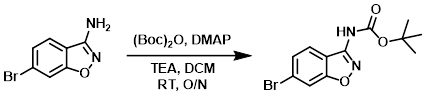

Example 2

A mixture of the SM (900 mg, 4.25 mmol), (Boc)2O (1.2 g, 5.1 mmol), TEA (686 mg, 6.8 mmol), and DMAP (72 mg, 0.6 mmol) in DCM (10 mL) was stirred at RT overnight. H2O was added and the layers were separated. The aq layer was further extracted with DCM. The combined organics were washed with brine, dried (Na2SO4), and concentrated. The crude material was purified by silica gel column chromatography to provide the product as a solid. [900 mg, 68%]

[Patent Reference: WO2010027500, page 117, ![]() (22.8 MB)]

(22.8 MB)]

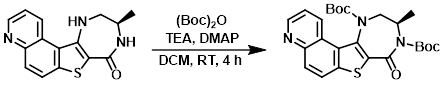

Example 3

To a solution of the SM (750 mg, 2.6 mmol) in DCM (10 mL) was added TEA (669 mg, 6.6 mmol) and DMAP (76 mg, 0.6 mmol). The mixture was stirred 5 min, then was treated with (Boc)2O (2.3 g, 10.6 mmol) at RT. The reaction was stirred at RT for 4 h, after which time the mixture was partitioned between H2O (50 mL) and DCM (100 mL). The org layer was dried (Na2SO4) and concentrated to provide the product as a brown solid. [700 mg, 56%]

[Patent Reference: WO2014149164, page 271, ![]() (23.7 MB)]

(23.7 MB)]

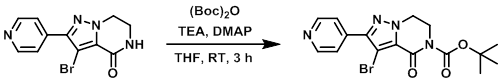

Example 4

To a suspension of the SM (7.5 g, 34.1 mmol), DMAP (0.83 g, 6.8 mmol), TEA (14.3 mL, 102 mmol) in THF (170 mL) was added (Boc)2O portionwise at RT. The reaction mixture was stirred at RT for 3 h. The mixture was diluted with DCM/H2O. The org layer was separated, dried (MgSO4), and concentrated. The resulting material was purified by Prep LC (120 g silica, 100% DCM to 95% DCM, 5% MeOH, 0.1% NH4OH) to provide the product. [12.4 g, 92%]

[Patent Reference: WO2015144799, page 92, ![]() (18.8 MB)]

(18.8 MB)]