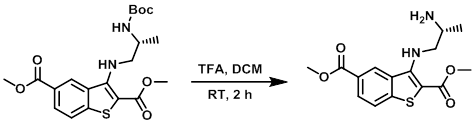

Boc Deprotection

(TFA)

Examples:

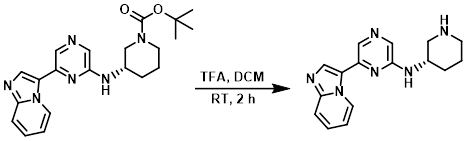

Example 1

A solution of SM (75 mg, 0.19 mmol) in DCM (1 mL) was treated with TFA (1 mL) for 2 h. The solvent was removed in vacuo and the crude was dissolved in 10% IPA/chloroform, washed with sat aq NaHCO3, brine, dried (MgSO4), and concentrated. The resulting material was purified by HPLC (H2O/ACN with TFA) to provide the product as a beige solid from MTBE/hexane. [25 mg]

[Patent Reference: WO2010016005, page 84, ![]() (11.3 MB)]

(11.3 MB)]

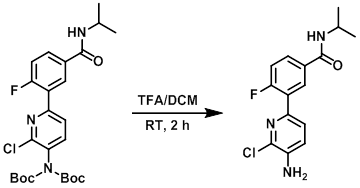

Example 2

The SM was treated with 25% TFA/DCM at RT for 2h, after which time the volatiles were removed in vacuo. The crude was diluted with EtOAc, washed with sat aq Na2CO3, then brine. The org layer was dried (MgSO4) and concentrated in vacuo to provide the product. [60%]

[Patent Reference: WO2010026121, page 40, ![]() (3.6 MB)]

(3.6 MB)]

Example 3

The SM (17.4 g, 59.7 mmol) in DCM (120 mL) was treated with TFA (23.0 mL, 299 mmol) and allowed to stir for 18 h at RT. Excess 1 N NaOH was added and the mixture was stirred vigorously for 15 min. The org layer was separated, dried (MgSO4), and concentrated in vacuo to provide the product as a brown solid. [9.95 g, 87%]

[Patent Reference: WO2014177977, page 43, ![]() (6.0 MB)]

(6.0 MB)]

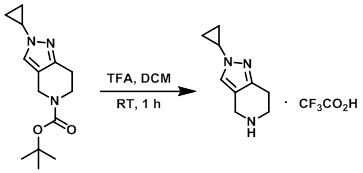

Example 4

To a solution of the SM (169 mg, 0.642 mmol) in DCM (5 mL) was added TFA (1 mL). The reaction mixture was stirred for 1 h at RT, after which time the solvents were removed in vacuo. The crude product was used without further purification.

[Patent Reference: WO2014177977, page 81, ![]() (6.0 MB)]

(6.0 MB)]

Example 5

To a solution of the SM (1.5 g, 3.5 mmol) in DCM (15.0 mL) at 0 C was added TFA (3.0 mL). The reaction mixture was stirred at RT for 2 h, after which time the mixture was co-distilled with DCM 4-5 times in vacuo. The resulting material was triturated with ether to provide the product as an off-white solid. [1.3 g, 95%]

[Patent Reference: WO2014149164, page 261, ![]() (23.7 MB)]

(23.7 MB)]

Example 6

To a solution of the SM (1.4 g, 5.8 mmol) in DCM (15 mL) at 0 C was added TFA (4.4 mL, 58 mmol). The ice bath was removed and the reaction mixture was stirred at RT for 3 h. The solvents were removed in vacuo and the residue was diluted with DCM. The mixture was cooled to 0 C and neutralized with sat aq NaHCO3. The resulting heterogeneous mixture was allowed to warm to RT and stir for 1 h. The mixture was filtered through a phase separator and the retained aq phase was washed thoroughly with DCM. The solvent was removed in vacuo to provide the product. [0.85 g, 98%]

[Patent Reference: WO2016014463, page 66, ![]() (6.7 MB)]

(6.7 MB)]