SEM Protection

(SEM-Cl + Strong Base)

Examples:

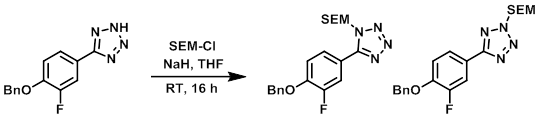

Example 1

To a solution of the SM (270 mg, 1.0 mmol) in THF was added NaH (44 mg, 1.1 mmol) in four portions. The resulting mixture was stirred at RT for 15 min, after which time was added SEM-Cl (0.19 mL, 1.0 mmol). The reaction mixture was stirred at RT for 16 h. The mixture was quenched by the addition of H2O, then diluted with EtOAc. The org layer was separated and the aq layer was further extracted with EtOAc (2x). The combined organics were washed with brine, dried (MgSO4), and concentrated. The resulting material was purified by flash chromatography (eluting with 5-20% EtOAc/heptane) to provide the product as a white solid. [270 mg, 67%]

[Patent Reference: WO2012069948, page 58, ![]() (3.9 MB)]

(3.9 MB)]

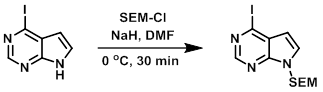

Example 2

A solution of the SM (8.1 g, 33.1 mmol) in DMF (165 mL) was cooled 0 C and NaH (60% in mineral oil, 1.98 g, 49.6 mmol) was added. After 30 min, SEM-Cl (7.02 mL, 39.7 mmol) was added and the reaction was stirred at 0 C for another 30 min. The mixture was poured into H2O (500 mL) and extracted with EtOAc (2 x 150 mL). The combined organics were washed with brine (150 mL), dried (Na2SO4), and concentrated. The resulting material was purified by silica gel chromatography (0-25% EtOAc/heptane) to provide the product as an oil that solidified upon drying on a vacuum pump. [11.1 g, 89%]

[Patent Reference: WO2012149280, page 51, ![]() (4.1 MB)]

(4.1 MB)]